In today's mobile machines, such as construction machines, agricultural machines and special vehicles, terminal boxes are still widely used. Known problems of this technology are the size and a possible dust and water ingress or condensation. This leads to corrosion and unnecessary downtime. In addition to the potential for errors during operation, the assembly and wiring of the required individual parts takes an enormous amount of time. Once the terminal box has been assembled after many hours, further valuable working time is invested in troubleshooting due to incorrectly under-clamped or reversed strands.

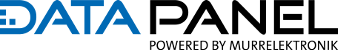

Our robust xtremeDB passive distributors are completely different on the road. They allow efficient linking of the control system with up to 16 existing sensors, hydraulic valves or work lights. The proven and widely used DT connector is used for the plug-in connections. Integrated LEDs reliably indicate the current signal status. This is a major advantage, especially during commissioning and troubleshooting. The housings of the passive distributors are made of reinforced polyamide and are completely encapsulated. This ensures maximum protection in accordance with IP69K. At the same time, excellent resistance to hydraulic oils, diesel, gasoline, lubricants and many other media is achieved. The temperature range is -40°C to +80°C. Instead of 16 lines, only one trunk line needs to be laid to connect the distributor to the control system. In case of change or damage, this (as well as the signal lines) can be replaced quickly and easily.

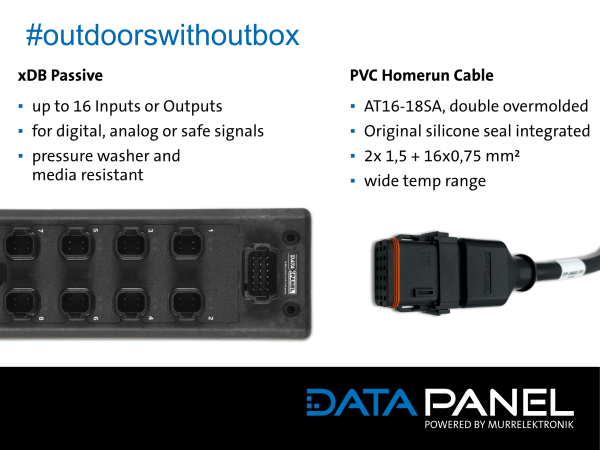

The trunk lines are available as a highly flexible PUR variant or in the new, inexpensive PVC variant for fixed installation. The factory single-wire seal of the DT connector is completely overmolded with PVC. This double sealing barrier permanently fulfills all protection classes up to and including IP69K.

In addition, the PVC trunk line offers good UV, cold, weather and chemical resistance - perfect for extreme operating conditions. The optional protective tube only has to be snapped onto the integrated corrugated hose connection - cable ties and hose clamps bye.

In summary, the robust xtremeDB passive distributors in combination with the PVC trunk line offer an economically advantageous solution and space-saving alternative to terminal boxes. Alternatively, they bring a modular, pluggable extension level to the wiring harness. In any case, with this modular installation, your machine gains in quality, future viability and a greatly improved repair option.